Most people assume that refilling and remanufacturing a laser toner cartridge is almost the same.

Here I bring to you the various and vast differences between the two:

Refilling:As the word itself says , it is basically just re-inking your exhausted toner cartridges , since OEMs charge a huge amount for new cartridges , almost over 55% of all Laser printer users opt for refilling in India.

Refilling can be done in 3 ways

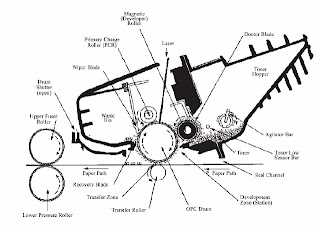

a)the mechanical way : the most usual way is dismantling the whole cartridge , you basically have 2 sections to the cartridge the toner section and the hopper section , the toner section holds the toner (which is basically a black powder which consists of carbon or dye , magnetic materials and plastic materials) and the hopper section which houses the other components.So herein a refiller just fills in the toner section with a new pack or bottle of toner and reassembles the cartridge back to the original condition.Also in the process the waste bin would be cleared.

b)A refill kit : Hundreds of people sell do-yourself-kits ,even though its not very popular in India ,there are a few companies who make use of these kits.

c)Punch a hole:the fastest way to refill a cartridge and can be done by absolutely anybody is by punching a hole in the toner section and filling in the toner and sealing the hole to hold the toner , in this case usually refillers do not clean the waste bin which holds the remnants of previous usage which would lead to toner spillages.

Remanufacturing :

Here I bring to you the various and vast differences between the two:

Refilling:As the word itself says , it is basically just re-inking your exhausted toner cartridges , since OEMs charge a huge amount for new cartridges , almost over 55% of all Laser printer users opt for refilling in India.

Refilling can be done in 3 ways

a)the mechanical way : the most usual way is dismantling the whole cartridge , you basically have 2 sections to the cartridge the toner section and the hopper section , the toner section holds the toner (which is basically a black powder which consists of carbon or dye , magnetic materials and plastic materials) and the hopper section which houses the other components.So herein a refiller just fills in the toner section with a new pack or bottle of toner and reassembles the cartridge back to the original condition.Also in the process the waste bin would be cleared.

b)A refill kit : Hundreds of people sell do-yourself-kits ,even though its not very popular in India ,there are a few companies who make use of these kits.

c)Punch a hole:the fastest way to refill a cartridge and can be done by absolutely anybody is by punching a hole in the toner section and filling in the toner and sealing the hole to hold the toner , in this case usually refillers do not clean the waste bin which holds the remnants of previous usage which would lead to toner spillages.

Remanufacturing :

Simply stated, remanufacturing is the process of disassembly of products during which time parts are cleaned, repaired or replaced then reassembled to sound working condition. A more detailed definition of remanufacturing has been adopted by The Remanufacturing Institute (formerly the Remanufacturing Industries Council International).

A product is considered remanufactured if:

• Its primary components come from a used product.

• The used product is dismantled to the extent necessary to determine the condition of its components.

• The used product's components are thoroughly cleaned and made free from rust and corrosion.

• All missing, defective, broken or substantially worn parts are either restored to sound, functionally good condition, or they are replaced with new, remanufactured, or sound, functionally good used parts.

• To put the product in sound working condition, such machining, rewinding, refinishing or other operations are performed as necessary.

• The product is reassembled and a determination is made that it will operate like a similar new product.

Parts of a Laser Toner Cartridge

No comments:

Post a Comment